Welcome to the Company

Aluminum composite panel

| |||||||||||||

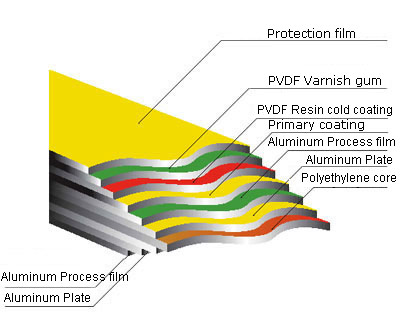

| í░FLORESí▒ Aluminum composite panel is consisted of 3 layers, the surface and back covers of high strength aluminum alloy sheets and the core of nontoxic low density polyethylene (PE) sheet. The painting in the surface and back aluminum sheets are from PPG.VALSPAR of USA and Becker of Sweden. | |||||||||||||

|

| |||||||||||||

| Advantages | |||||||||||||

|

| Anti-toxicity and Safety The aluminum sandwiched core is made of low density polyethylene; the exterior aluminum sheet is uninflammable; the coating itself performs durable & flavourless. í░FLORESí▒aluminum composite panel fulfills the fireproof requirements . |

| Corrosion resistance: The surface coating is the KTNR500 fluorine-carbon resin coating manufactured by PPG or Becker , can effectively resist the attack of acid rain, air pollution and ultraviolet ray, featuring long useful life, high absorption, excellent gloss, aging resistance and color fastness. |

| Free of light pollution Since the fluorine-carbon coating surface is matte (gloss about 35), light will be diffusively reflected without causing light pollution. |

| Strong self-cleaning Since the special molecular structure of KYNa500 in the surface fluorine-carbon resin coating, dust cannot be absorbed thereon, so it has strong self-cleaning ability. |

| Workability The excellent physical characters of í░í░FLORESí▒ ACPs, such as Tensile Bonding Strength, Simple Bending Strength, Bending Moment, etc., expand the boundary of panel fabrication. These same properties also allow you fabricating stability and installation safety. Moreover, the P.E core between aluminum is soft enough that fabrication is much easier and more convenient. |