|

|

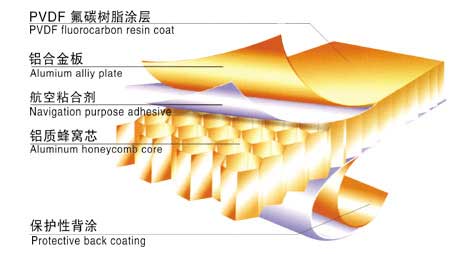

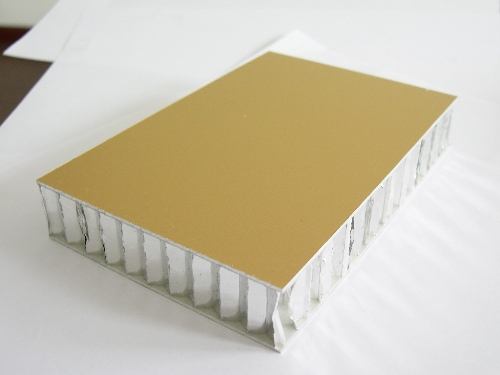

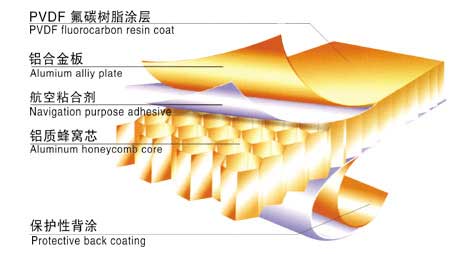

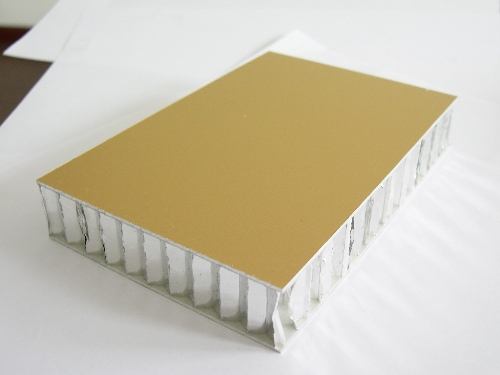

Adopting “honeycomb sandwich” structure, “FLORES” aluminum honeycomb panel is a kind of hi-tech and environment-friendly panel by tightly sticking aluminum alloy sheets to aluminum honeycomb core, and manufactured by currently update navigation technology and advanced automacti production equipment. Its face and back plates are strength aluminum alloy, and coated with weather-resistant fluorocarbon resin and polyester respectively! “FLORES” aluminum honeycomb panel has the advantage of light weight, high strength, goof rigidity, strong anti-corrosion and good stability. Compared with other wall decoration materials, aluminum honeycomb panels has better heat preservation and sound insulation. The reason is that the air between the face and the back aluminum sheet is separated into lost of cellular closed holes, and heat transmission and sound wave are extremely restricted.

Aluminum Honeycomb Panel was previously used only in the aviation field. With the economic development in recent years, it has been gradually extended to civilian area, such as decorative building materials, vehicles, wall panels of vessels and so on.

Aluminum Honeycomb Panel is made up of pure aluminum.It is a green product, which is easily recovered and in line with the development direction of new materials in the future.

|

|

|

|

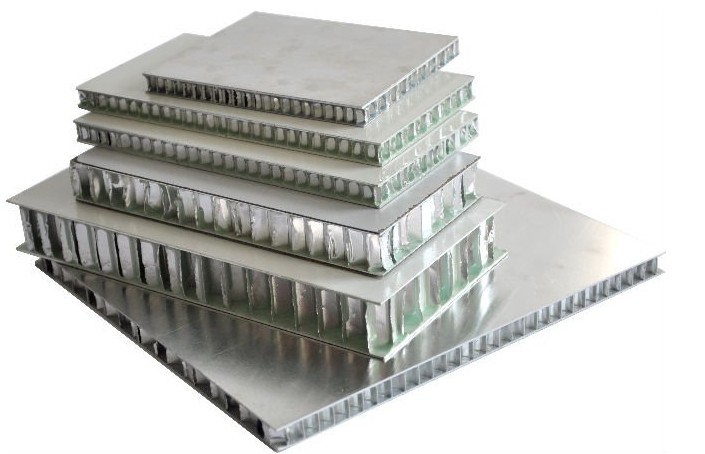

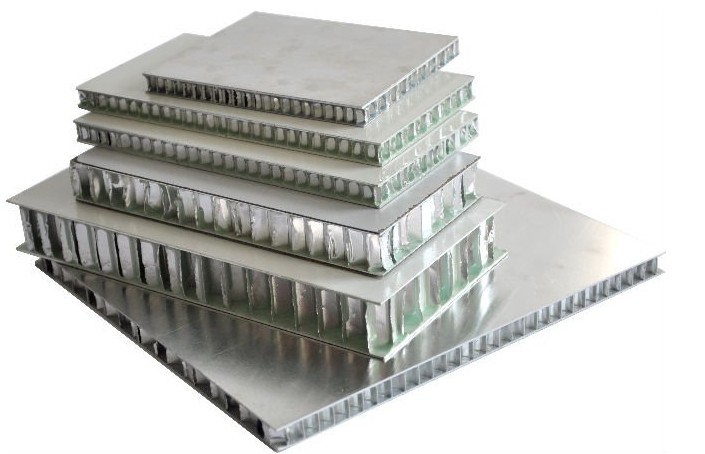

Aluminum honeycomb panel specifications

Total Thickness: 6mm-200mm

Thickness of face and back aluminum sheets: 0.5mm-3mm

Standard size: 1,220 x 2,440mm

Width: 1,220, 1,250, 1,270, 1,500, (≤2000mm)

Length: standard 2,440mm and customized length ≤ 10,000mm

Colors:RAL colors

|

| Characteristics of aluminum honeycomb panels: |

|

1.Sound insulation, heat insulation, heat preservation: the honeycomb itself doesn’t possess the capability of sound insulation and heat insulation, but the structure of honeycomb sandwich possesses very good capability of sound insulation and heat insulation. In the common used aluminum honeycomb core of the honeycomb sandwich, the volume of entity material is only 1%~3% of the total. Within the other space, there is the air that is closed in. The honeycomb sandwich is of very good heat insulation and sound insulation capability because of the air’s performance of sound insulation and heat insulation is better than any solid materials and limits the heat energy and sound wave greatly. | |

|

2.Fireproofing: after testing and authenticating by the National Center for Quality Supervision and Testing of Fireproofing Building Materials, various performance indexes of the materials are all conformed to the regulations and requirements of flame-resisting material. The flame-resisting feature of the materials is up to level GB-8624-A according to the national standard GB-8624-1997 | |

|

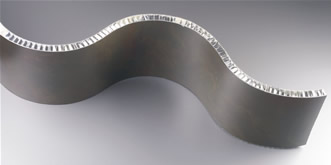

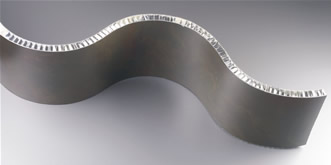

3.Excellent flatness and rigidity: because the honeycomb core is under stress vertically, every board is with incalculable fixed honeycombs and will not produce moving, so the board will be very stable and keep its form unchangeable even if striking by outside force (such as typhoon etc.). Aluminum honeycomb sandwich composed of many dense honeycombs pinning against each other is just like many small I shape girders that can bear the pressure separately from the direction of face sheet. This makes the board being pressed evenly, ensures its intensity of pressure bearing and keeps high flatness when the face sheet is with larger area. | |

|

4.Light material and energy saving: the weight of aluminum honeycomb sandwich-core is only 1/5 as aluminum plate and 1/10 as steel plate but it’s with the same rigidity. The weight of per square meter aluminum honeycomb sandwich, with total thickness 15mm, face sheet of aluminum 1.0mm and bottom sheet of aluminum 0.8mm, is only 6kg. The weight of per square meter aluminum honeycomb sandwich, with total thickness 10mm, face sheet of aluminum 0.5mm and bottom sheet of aluminum 0.5mm, is only 4 kg. Comparing with the weight of traditional aluminum-plastic board, the weight of per square meter is less about 2 kg. But its rigidity is more than 2 times stronger than the rigidity of aluminum-plastic board. It can compare beauty with aluminum board of 4mm thickness. Its price/performance ratio is evidently high than the price/performance ratio of aluminum-plastic board and aluminum board. So the materials can be saved effectively. | |

|

5.Environment protection: the material will not emit any gas material that is harmful to human health. Easy to clean and can be recycled. | |

|

6.Moisture-proof: the material will not absorb water. Its surface is applied filming technology. It will not change color for long. In the damp environment, the material will not be mildewed or distorted. | |

|

7.Antisepsis: after testing, the material dipped in 2%HCL solution for 24 hours without any change. The material dipped in Ca (OH) 2 saturated solution for 24 hours without any change.。 | |

|

8.Easy installation: with the aluminum alloy keel, the installation will be convenient, fast, both saving time and labor; it can be installed, dismantled and transferred repeatedly. | |

|

9.Excellent shock-absorption performance: because of many dense honeycombs pinning against each other is just like many small I shape girders that can bear the pressure separately from various directions, so it’s with stronger antiseismic ability | |